Company Profile

Greeting

Since our establishment in 1970 (Showa 45), we have been committed to maintaining a track record of profitability and zero personal accidents. Additionally, we strive to achieve effective recycling of metal resources and environmental preservation, contributing to the local community by recovering even the smallest traces of metal.

Chairman of the Board

The company was established in 1970, when I was 31 years old.

I was convinced that the scrap metal trade would be a perpetual and promising business and decided to start my own business.

I am from Kumamoto Prefecture and joined Sowa Metals K.K. in Edogawa Ward, Tokyo. Here, I was fortunate to have the opportunity to hear various valuable stories from many company presidents in the same trade, which I have used as reference for my own business.

My father’s farm work education also proved extremely useful in every turn of my life, and in the company, I have always kept a keen eye on maintaining a safe factory environment and also recognize the importance of providing employees with a stable life.

My father and the presidents of the other companies taught me that the foundation in managing a company was to ensure that the employees do not feel uneasy or uncomfortable in performing their tasks and to eliminate dissatisfied in their daily lives. We have been able to carry on operations with staying out of the red and no workplace accidents since its establishment in 1970.

I believe that this achievement is a result of the coexistence of a better sense of cooperation and the spirit of mutual prosperity among our employees. We hope to continue to serve our clients and the society on the basis of this policy.

I have now been appointed as Chairperson, and as my successor, Noriaki Taguchi has been appointed as President and CEO.

I hope to have your continued patronage for us.

Noriaki Taguchi,

Noriaki Taguchi,President & CEO

In November 2013, I, Noriaki Taguchi, assumed the position of the President and CEO of Taguchi Metals Corporation.

On the basis of our corporate philosophy of coexistence and mutual prosperity with the local community, and always putting the benefits of our clients and the local community first, we will strive to maintain a record of profitability without accidents since our establishment.

Succeeding the management policy of my predecessor, we will ensure further technological advances to address the various changes in the metal recycle market, strive to provide a safe workplace and promote environmental conservation.

Employees are valued and nurtured through training and education sessions to ensure that they are capable of meeting the requests of the local community and our clients. We will never be satisfied with our present situation and will continue to challenge ourselves into the future.

We hope to receive your continued support and patronage as we exert our efforts to keep a beautiful factory, nurture courteous employees, and maintain operations with staying out of the red and no workplace accidents.

Profile

- NAME

- TAGUCHI METALS CORPORATION Taguchi Metals Corporation TMC

- Head office

- Taguchi Bldg. 1-20-4 Nakaochiai, Shinjuku, Tokyo 161-0032 Japan

Phone: +81 3-5386-1000 Fax: +81 3-3367-7001 - Establish-ment

- November 21, 1974

(Started as Taguchi Shoten in September, 1970) - Capital

- JPY 20,000,000

- Sales and Net Profit

-

Sales Capital 2008.8 10887 294 2009.8(a year after the Lehman Shock) 4888 12 2010.8 6215 222 2011.8 7153 207 2012.8 5997 37 2013.8 6354 168 2014.8 6227 201 2015.8 5428 74 2016.8 3708 12 2017.8 4868 171 2018.8 6253 280 2019.9 5551 228 2020.8 4714 102 2021.8 7933 471 2022.8 11364 256 2023.8 10586 84 (Unit: Millions of yen)

- Directors

-

- Chairperson and Managing Director

- Takeshi TAGUCHI

- President and Managing Director

- Noriaki TAGUCHI

- Senior Managing Director

- Kiyoshi ITOU

- Executive Director General

Manager of Sales Department - Yuzo KOBAYAKAWA

- Director

- Rika TAGUCHI

- Director

- Tkeko TAGUCHI

- Director

- Masahiro AKIBA

- Director

- Tomohito YAMANAKA

- Auditor

- Shizuo NAKAMURA

- Employees

- 90(as of April 2023)

- Business

-

- Recycling of steelmaking raw materials, nonferrous metal materials and waste home appliances

- Collection and transportation of industrial waste

- Intermediate treatment of industrial waste

- Construction demolition work

- Automobile demolition for recycling

- Associated Company

-

- DEN Corporation (Taguchi Sansho Co., Ltd. changed its name in December 2019)

- Nakai Corporation

Banks

- Bank of Mitsubishi UFJ(Takadanobaba branch)

- Mizuho Bank(Takadanobaba branch)

- The Shoko Chukin Bank(The main office marketing dept.)

- Tokyo Shinyo Kinko(Nakai branch)

- Joyo Bank(Shinjuku branch)

Major Clients (listed in random order)

- Nippon Steel Co., Ltd.

- Tokyo Steel Co., Ltd.

- Tokyo Tekko Co., Ltd.

- Tokyo Ko-tetsu Co., Ltd.

- Chiyoda Steel Co., Ltd.

- Jonan Steel corporation

- Mukoyama Steel Works Co., Ltd.

- Itoh Iron & Steel Co., Ltd.

- JFE Bars & Shapes Corporation

- Kyoei Steel Ltd.

- Various home appliance recycling plants

- National and local government offices

- MM&KENZAI Corporation

- ITOCHU Metals Corporation

- Hanwa Co., Ltd.

- Mitsui Kinzoku Recycle Co., Ltd.

- Toyota Tsusho Material Incorprated

- Honda Trading Corporation

- JX Metal Trading Co., Ltd.

- Sakai Chemical Industry Co., Ltd.

- Ahresty Corporation

- Keiaisha Co., Ltd.

- Sumitomo Metal Mining Co., Ltd.

- Nippon Yakin Kogyo Co., Ltd.

- Daiki Aluminium Industry Co., Ltd.

- Asahi Seiren Co., Ltd.

- Komazawa Kinzoku Kogyo Ltd.

- S. S. Aluminum Co., Ltd.

- Mitsubishi Materials Corporation

- Rever Corporation

- Seinan Corporation

- Ishii Shoji Co., Ltd.

- Suzuki Shokai Inc.

500 other corporations in the industry(As of June 2024)

Affiliations

- Japan Iron And Steel Recycling Institute

- Tokyo Recycle Business Cooperative

- Ibaraki Prefecture Construction and Demolition industries Cooperative

- Kanto Tetsugen Cooperative

- Tokyo Hitetsu Kinzoku Shoko Kyoudou Kumiai

- Shimotsuma Koiki Shigen Cooperative

- Koga Recycling Cooperative

- Kogashi Industrial Association

- Metal Scrap Press Association

- Kekinzoku Doyukai

- Ibaraki Industrial Resources Recycling Association

Permits and Licenses

- Unified Supplier Qualification for all ministry and agency (Grade A).

-

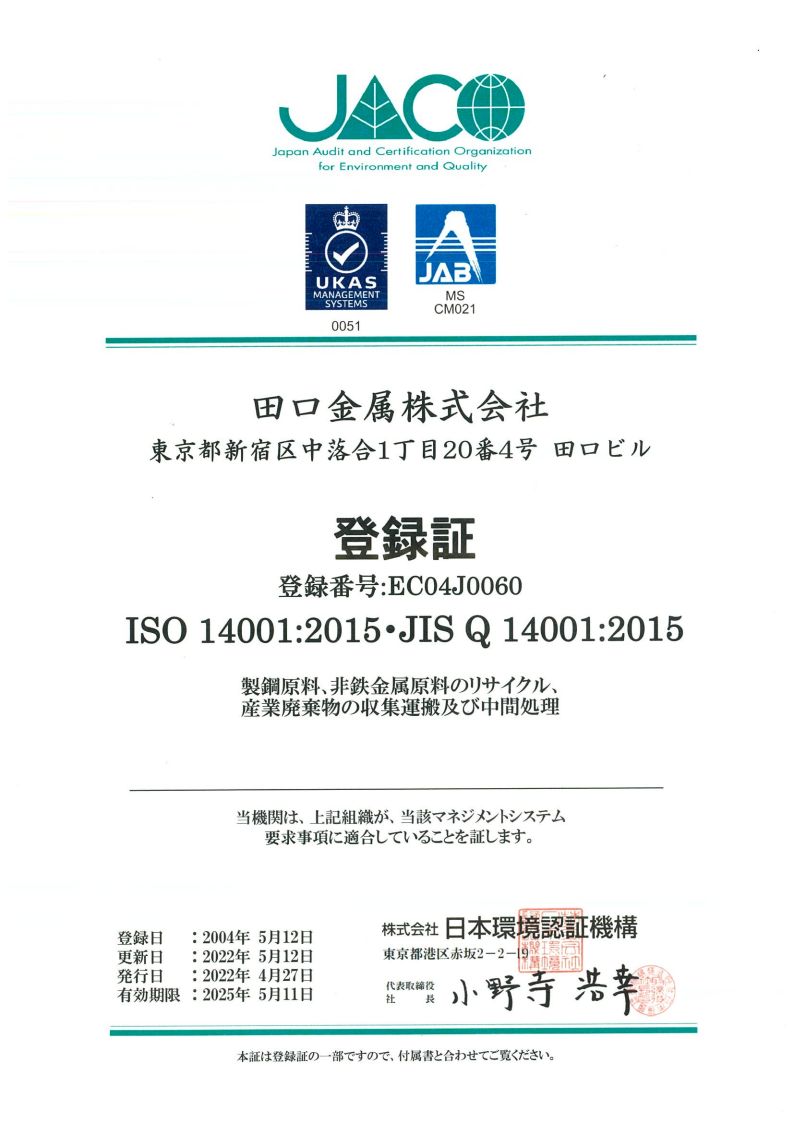

- ISO14001 Certification

- Audit and certification organization

- Japan Audit and Certification Organization for Environment and Quality (JACO)

- Registration#

- EC04J0060

- Date of Certification

- 2004/5/12

- Date of Renew

- 2022/5/12

- Industrial Waste Treatment License

- License#

- Ibaraki Prefecture 00821015294(Certificate of Excellence)

- Classification Segment

- Intermediate treatment of industrial waste (cutting ,compressing and shredding)

- Workplace and Types of Industrial Waste

- Okazato Plant (cutting ,compressing and shredding)

- Scrap metal, waste plastics, glass, concrete and ceramic scraps, wood scraps, paper, fiber, rubber scraps, and debris

- Tsukuba Plant (cutting,compressing)

- Scrap metal, waste plastics, glass, concrete and ceramic scraps, wood scraps

- Waste Reclamation Business Registration

- Registration Number

- Ibaraki Pref 4013(Tsukuba plant)

Ibaraki Pref 4014(Koga plant)

Ibaraki Pref 4022(Okazato plant) - Business contents

- Metal scraps

- Industrial Waste Collection and Transportation

- License Numbers

- Tokyo Metropolis 013-00-015294 (Certificate of Excellence)

Ibaraki Pref. 00801015294

Tochigi Pref. 00900015294 (Certificate of Excellence)

Gunma Pref. 01000015294 (Certificate of Excellence)

Saitama Pref. 01106015294

Chiba Pref. 01200015294 (Certificate of Excellence)

Fukushima Pref. 00707015294 (Certificate of Excellence)

Miyagi Pref. 00400015294 (Certificate of Excellence)

Kanagawa Pref. 01400015294 (Certificate of Excellence) - Nigata Pref. 01509015294

- Yamanashi Pref. 01900015294

- Nagano Pref. 2009015294

- Demolition of Construction License

- License Number

- Ibaraki Prefectural Governor (reg. 15) 147

- Metal Scrap and Second-hand Dealer License

- Automobile Recycling and Shredding License

- License Number

- Ibaraki Prefecture 20084002199

- Business Segment

- Pre-demolition (cutting)

- Recycled Resource Export Business Registration to China

- Registration Number

- A392170145

History

- 1970

- Established” Taguchi Shoten” in Sowa, Ibaraki (present Koga).

- 1971

- Began an operation at Shinjuku Plant. Dollar Crisis recession

- 1973

- Oil Crisis

- 1974

- Incorporated as Taguchi Metals Corporation.

Made Shinjuku Plant the head plant. - 1977

- Began an operation at Ibaraki Plant (Kitatone Industrial Park) Established Japan Recycling Metals Co., Ltd. (Nippon Saisei Kinzoku).

- 1978

- Established Taguchi Sansho Co. Ltd.

- 1980

- 10th Anniversary of Taguchi Metals

- 1983

- Constructed the Taguchi Metals Group Building (Nakaochiai, Shinjuku Ward).

- 1987

- Relocated Sowa Plant (sold and relocated from the Kitatone Industrial Park). 60-ton weigh station

- 1988

- Dissolved Japan Recycling Metals.

- 1989

- Began an operation at Tsukuba Plant. 60-ton weigh station

- 1990

- Established Yokohama Office.

- 1992

- Closed Yokohama Office.

- 1993

- Established nonferrous metal sorting plant at Ibaraki (Sowa) Plant.

- 1996

- Installed guillotine press at Tsukuba Plant.

- 1998

- Began an operation at Ibaraki New Yard (present Koga Plant). 80-ton weigh station

- 2000

- Licensed as a general construction business (Tokyo Metropolitan Government).

- 2001

- Acquired the right for direct sales to Tokyo Steel Manufacturing Co., Ltd. Utsunomiya Plant.

Obtained Unified Supplier Qualification for every ministry and agency (Grade A). - 2002

- Licensed as an industrial waste treatment for Tsukuba Plant. Closed the head plant (for the construction of Metropolitan

Expressway Central Circular Shinjuku Route). - 2003

- Registered disassembly business (Ibaraki pref.).

Constructed Ibaraki New Yard office building and plant building (present Koga Plant). - 2004

- Certified ISO 14001.

<4 locations: head office, Koga Plant, Sowa Plant and Tsukuba Plant>

Licensed as an automobile demolition and recycling for Tsukuba Plant. - 2005

- Licensed for recycled material export to China. Changed the plant names due to city/town mergers.

<Koga Plant (former Ibaraki new Yard) and Sowa Plant (former Ibaraki Plant)> Registered as an industrial waste recycler (Ibaraki Pref.) - 2007

- Began an operation at the 2nd Koga Plant.

Began an operation at Okazato Plant.

Established Steel and aluminum can area.

Installed a Guillotine press. 80-ton weigh station - 2008

- Completed Okazato Plant office building.

- 2009

- Certified ISO 14001 for all offices. (new for Okazato and the 2nd Koga Plants)

- 2010

- Extended and Renovated of the 2nd Koga Plant building.

Installed nonferrous metal sorting plant. - 2011

- Installed 100kw solar power generation equipment at Okazato Plant.

Installed the sorting line unit 2 and wind force specific gravity sorter at 2nd Koga Plant.

Licensed as an industrial waste treatment for Okazato Plant. - 2012

- Rebuilt an office and installed 80-ton weigh station and a radiation detector at Tsukuba plant.

- 2013

- Installed 111.6 kilowatts solar energy generation equipment at Koga Plant.

Installed 184.3 kilowatts solar energy generation equipment at the 2nd Koga Plant.

Installed 154.3 kilowatts solar energy generation equipment at Tsukuba Plant.

Installed magnetic eddy current sorting equipment. Installed 1000-ton Guillotine and constructed the building house of Guillotine at Tsukuba Plant - 2014

- Installed a metal sorter and a color metal sorter at Koga Plant.

- 2016

- The former Sowa Plant moved into the site of Okazato Plant and changed the name to Koga Okazato Group.

- 2017

- Installed scrap metal crusher at Okazato Plant.

- 2018

- Installed x-ray metal sorting machine and wind power metal sorting machine at the 2nd Koga Plant.

- 2019

- Installed the 3rd Line at Koga Plant.

Expanded of Tsukuba Plant. - 2020

- Established of Nakai Co., Ltd. and opened ”cafe NAKAI”.

- 2022

- Installed a briquette machine at Okazato Plant.

- 2023

- Installed a 1250HP shredder plant at Okazato Plant.

Sold the Souwa Plant.

Established the Koga 3rd plant.

ISO14001

ISO14001 certification

In 2003 we began certification acquisition activities of ISO 14001, and in May 2004 we acquired certification at four business sites, the head office, the Koga factory, the total factory and the Tsukuba plant. We will continue to promote environmental conservation activities by effectively recycling.

Environmental policy

Since our establishment in 1970, we have developed strong and trusting relationships with local communities and our clients, and strived at keeping our company’s record free of workplace accidents. With the technical skills we have acquired and achievements we have made in our primary business of recycling limited metal resources over the years, we have faithfully contributed to the formation of recycling-oriented society by effectively recycling the metal resources generated by local communities.

Environmental issues are becoming ever more complex. We consider such issues our primary concern and continue to promote environmental protection in close cooperation with local governments and residents.

We hereby establish our basic policies for environmental protection.

Company policy

- Our business activities aim to increase the recycling volume of metal resources and facilitate the acquisition of licenses and qualifications.

- We are continuously aware of the environmental impact of our business activities, promote energy conservation, strive to reduce noise and vibration, and minimize our impact on the environmental.

- We rigorously enforce pollution prevention and promote the continuous improvement of our environmental management system, such as the implementation of solar power generation, to enhance our environmental performance.

- We will comply with relevant environmental regulations, agreements with the local community, stakeholders, and contractual obligations related to our products and services.

- This environmental policy will be made known to all individuals working within or for our organization, as well as the local community and the general public.”

2022/9/1

Taguchi Metals Co., Ltd

President & CEO, Noriaki Taguchi