Business contents

Recycle flow

We think that we want to be a recycling company that can handle all processes safely from all customers, reduce load on the environment and effectively recycle limited metal resources.

We mainly pick up and process iron scrap generated by plant and building dismantling and sorting shredder mixed metal. With mixed metal sorting, we do things with various sorting machines, as well as thorough quality control by carrying out appropriate recycling processing, as well as thoroughly implementing quality management based on the achievements and know-how that we have built over the years.

Iron Recycle

We think that we want to be a recycling company that can handle all processes safely from all customers, reduce load on the environment and effectively recycle limited metal resources.

We mainly pick up and process iron scrap generated by plant and building dismantling and sorting shredder mixed metal. With mixed metal sorting, we do things with various sorting machines, as well as thorough quality control by carrying out appropriate recycling processing, as well as thoroughly implementing quality management based on the achievements and know-how that we have built over the years.

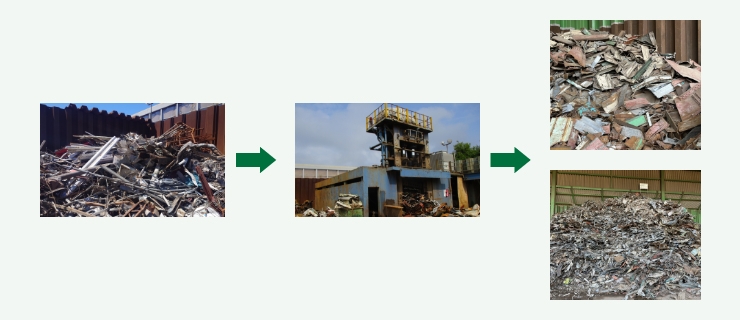

Shredding process

A lot of kind of metal scraps are shredded and separated to steel , mixed metal and dust.

After processing, shredded mixed metal is processed in Koga factory

Cutting process

Cut a long material such as iron plate, pipe, H steel in a short time according to the size suitable for the suppliers.

Compressing process

Compress thin materials such as empty cans and new scraps and reduce it to box shape.

Briquetting process

Turning scrap is compressed by a briquetting machine.

Gas cutting process

Thick and large materials that cannot be guillotined, such as heavy scrap machinery and tanks have made them smaller by gas cutting.

Cutting by excavators with cutter

Long, relatively thin mold steel, pipes, etc. made shorter lengths by a hydraulic excavator with cutter.

Nonferrous recycling

At our company, shredder mixed metal shredded for automobiles and waste household appliances is sorted according to materials such as aluminum scraps, stainless steel scraps, copper scraps, brass scraps by any sorting machine / hand sorting.

Other nonferrous scraps are made into raw materials by crushing process, plasma cutting, cutter cutting, press working, peeling processing etc. for each kind.

Shredded mixed metals sorting process

Shredder Mix Metal is selected according to extremely high accuracy and is shipped stably as end user’s furnace material at uniform quality with metal material.

This Mixed Metal is managed and stored metal component data for each source factory and material raw material, and its contents are also reported to the source.

This ingredient report is effectively used as an important material that leads to improvements in shredder plants with great trust from suppliers etc.

Shirring process

The radiator of air conditioner is cut by shirring machine and remove the steel edge. This radiator was properly temporarily treated at the household appliance processing factory.

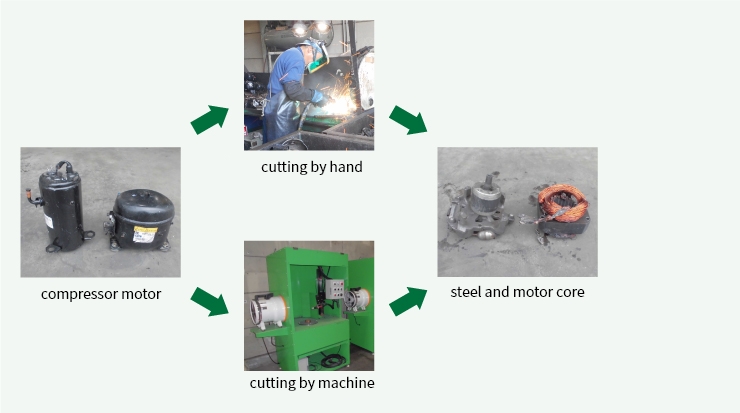

Shell cutting (compressor motor)

Household electric appliance Air conditioner · The compressor collected from the refrigerator is cut with a shell cutting machine and separated into iron scrap and motor core. This compressor was properly temporarily treated (CFC, oil, etc.) at the household appliance processing factory.

Compressing process (non-ferrous scrap)

Aluminum sash scraps, aluminum cans, etc. are divided for each material, compressed and reduced to box type.

Plasma cutting

Cut large stainless-steel scraps such as stainless-steel plants, tanks, pipes and bathtubs to the proper size with plasma.